Atari Jaguar FPGA Console Project

Project Overview

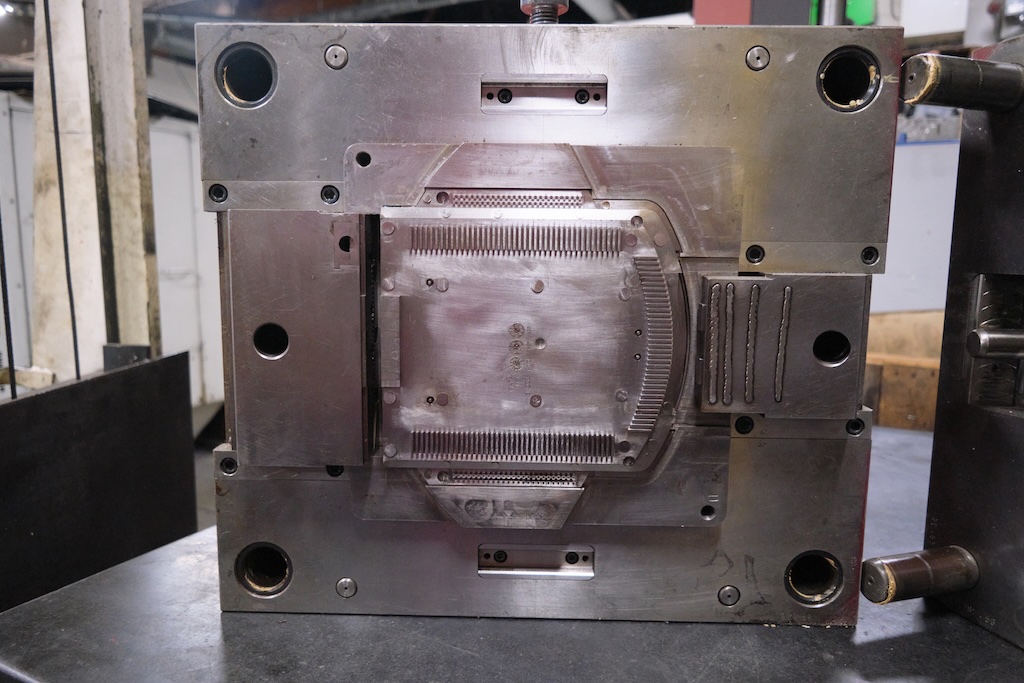

An ambitious exploration of domestic electronics manufacturing using recovered Atari Jaguar injection molds to create an FPGA-based universal game system simulator. The project investigated the feasibility of consumer electronics production in the United States.

Historical Context

• Atari Jaguar: First 64-bit game console (famous commercial failure)

• Recovered injection molds from same LA facility making Starlink terminals

• Molds were literally rusting outside when discovered

• Opportunity to save $500K-$1M in new tooling costs

Manufacturing Investigation

Core research question: Can consumer electronics be manufactured competitively in the United States?

• Domestic supply chain exploration

• Cost comparison with Shenzhen ecosystem

• High-value engineering vs. volume production

• Domestic partner capabilities assessment

Technical Approach

• FPGA-based universal game system emulation

• Existing Jaguar enclosure with new electronics

• Custom circuit board design for FPGA implementation

• Multiple retro gaming system support

• Modern manufacturing techniques applied to vintage design

Production Results

Successfully produced clear injection molded Atari Jaguar cases:

• Demonstrated domestic injection molding capabilities

• Validated mold recovery and refurbishment process

• Created unique transparent gaming console enclosures

• Established relationships with domestic manufacturing partners

Challenges and Lessons

Project faced significant administrative and execution challenges:

• Complex business coordination requirements

• Administrative overhead of domestic manufacturing

• Scaling challenges for consumer product volumes

• Cost competitiveness vs. international production

Industry Insights

• Domestic manufacturing excellence in high-value applications

• Challenges of volume consumer electronics production

• Opportunity costs of domestic vs. international manufacturing

• Importance of project management in complex manufacturing

Cultural Impact

The project preserved an important piece of gaming history while exploring modern manufacturing approaches, contributing to discussions about reshoring electronics production and the viability of domestic consumer electronics manufacturing.

Rauchwerk Research

Rauchwerk Research